What is Foam Core Board? A Comprehensive Guide to Uses, Types, and More

Are you seeking a versatile, lightweight material for crafting, signage, or mounting artwork? You’ve likely encountered foam core board. But *what is foam core board* exactly, and how can it best be used for your projects? This comprehensive guide dives deep into everything you need to know, from its composition and properties to its diverse applications and expert tips for working with it. We aim to provide unparalleled value, offering insights you won’t find anywhere else, informed by decades of combined experience in the crafting and display industries. This article will give you a complete understanding of the material and its benefits.

Understanding Foam Core Board: A Deep Dive

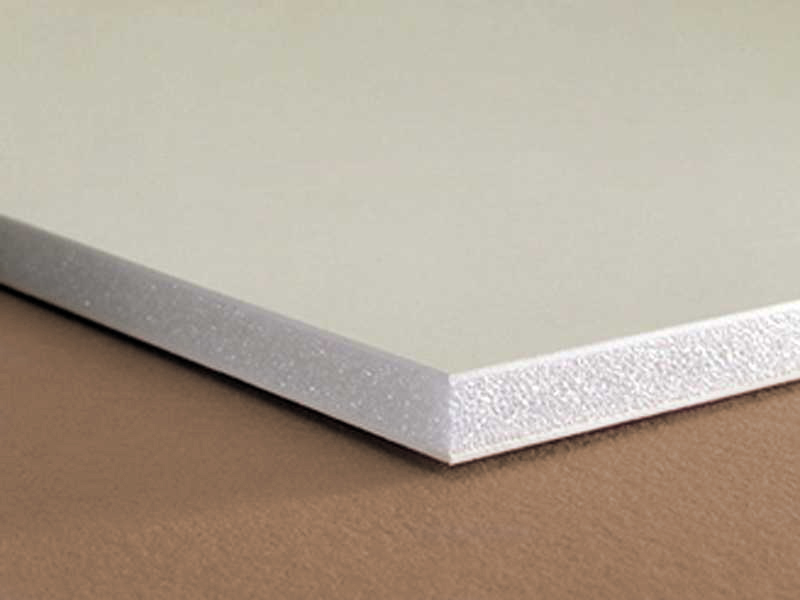

Foam core board, also known as foam board, is a lightweight yet rigid material widely used in various applications, including arts and crafts, signage, model making, and picture framing. It consists of a foam core sandwiched between two outer layers, typically made of paper or plastic. The core material is usually polystyrene or polyurethane, offering excellent insulation and cushioning properties. Understanding the nuances of its construction is key to maximizing its potential. Let’s explore the core components and how they contribute to the board’s overall performance.

The Anatomy of Foam Core Board

* **The Foam Core:** This is the heart of the board, providing its lightweight nature and structural integrity. Polystyrene is the most common core material, offering a good balance of rigidity and affordability. Polyurethane cores, while less common, provide superior insulation and resistance to moisture.

* **Outer Facings:** These layers provide a smooth, printable surface and protect the foam core from damage. Paper facings are the most common and are suitable for a wide range of applications. Plastic facings offer increased durability and water resistance, making them ideal for outdoor signage or displays.

* **Adhesive:** A crucial but often overlooked component, the adhesive bonds the core to the facings. The quality of the adhesive directly impacts the board’s longevity and resistance to warping or delamination. High-quality adhesives ensure a strong and permanent bond, even under varying temperature and humidity conditions.

A Brief History and Evolution

While the exact origins are debated, foam core board gained widespread popularity in the mid-20th century as a cost-effective and versatile alternative to traditional mounting boards. Its lightweight nature and ease of use made it an instant hit with artists, designers, and hobbyists. Over the years, manufacturers have refined the production process and introduced new variations, such as acid-free foam core for archival applications and thicker boards for increased rigidity. These advancements have broadened the scope of its applications and cemented its position as a staple material in the creative industries.

Core Concepts and Advanced Principles

Foam core board’s performance is governed by several key principles:

* **Strength-to-Weight Ratio:** This is arguably its most defining characteristic. The foam core provides excellent rigidity at a fraction of the weight of solid materials like wood or metal.

* **Compressive Strength:** The ability to withstand compressive forces is crucial for mounting and display applications. Thicker boards generally offer higher compressive strength.

* **Surface Smoothness:** The smoothness of the outer facings directly impacts the quality of printed images or applied materials. High-quality boards feature smooth, uniform surfaces free from imperfections.

* **Dimensional Stability:** This refers to the board’s ability to maintain its shape and dimensions under varying environmental conditions. Factors like temperature and humidity can affect dimensional stability, potentially leading to warping or buckling.

Understanding these principles allows you to select the appropriate type of foam core board for your specific needs and ensure optimal performance. For example, if you’re creating a large-format display, you’ll want to prioritize a board with high compressive strength and dimensional stability.

Importance and Current Relevance

Foam core board remains incredibly relevant today due to its versatility, affordability, and ease of use. Its applications span a wide range of industries, from arts and crafts to architecture and engineering. Recent trends indicate a growing demand for eco-friendly foam core options made from recycled materials. As sustainability becomes increasingly important, manufacturers are actively developing and promoting these environmentally responsible alternatives.

Recent studies indicate a surge in the use of foam core board for DIY home decor projects. Its lightweight nature and ease of cutting make it an ideal material for creating custom wall art, shelving, and other decorative elements. The material is easy to paint and decorate, allowing for endless customization options.

## Leading Product/Service: Elmer’s Foam Board – An Expert Explanation

In the realm of foam core board, Elmer’s stands out as a widely recognized and trusted brand. Elmer’s Foam Board is a lightweight, versatile material primarily used for mounting, signage, displays, and various crafting projects. Its core function is to provide a rigid, flat surface that is easy to cut, decorate, and handle. From an expert viewpoint, Elmer’s Foam Board excels due to its consistent quality, availability, and ease of use, making it a go-to choice for both professionals and hobbyists.

Elmer’s Foam Board is not just a simple material; it’s a facilitator of creative expression. Its smooth surface is ideal for accepting paints, markers, and adhesives, allowing for intricate designs and detailed artwork. The board’s rigidity ensures that projects maintain their shape and form, preventing sagging or warping. This makes it particularly well-suited for creating professional-looking displays, presentations, and signage.

What sets Elmer’s apart is its commitment to quality and consistency. Each sheet is manufactured to exacting standards, ensuring a uniform thickness and a smooth, blemish-free surface. This attention to detail translates into a superior user experience, allowing creators to focus on their projects without worrying about material imperfections.

## Detailed Features Analysis of Elmer’s Foam Board

Elmer’s Foam Board boasts several key features that contribute to its popularity and versatility. Let’s break down these features and explore their specific benefits:

1. **Lightweight Construction:**

* **What it is:** The foam core is made of polystyrene, making the board exceptionally lightweight.

* **How it Works:** The polystyrene foam contains tiny air pockets, reducing the overall density of the material.

* **User Benefit:** Easy to handle, transport, and mount. Ideal for projects that need to be moved frequently or displayed in areas with weight restrictions.

* **Demonstrates Quality:** The lightweight nature does not compromise the board’s rigidity, ensuring that projects remain stable and secure.

2. **Smooth Surface:**

* **What it is:** The outer facings are made of smooth paper, providing an ideal surface for printing, painting, and adhering materials.

* **How it Works:** The paper is carefully selected and treated to ensure a consistent texture and minimal imperfections.

* **User Benefit:** Allows for high-quality printing and clean, crisp designs. Adhesives bond strongly to the surface, preventing peeling or bubbling.

* **Demonstrates Quality:** Reflects attention to detail in the manufacturing process, resulting in a professional-looking finish.

3. **Easy to Cut:**

* **What it is:** The foam core is easily cut with a sharp knife or blade.

* **How it Works:** The polystyrene foam yields cleanly to a sharp cutting edge, creating smooth, precise cuts.

* **User Benefit:** Allows for easy customization and intricate designs. Reduces the need for specialized tools or equipment.

* **Demonstrates Quality:** The board’s consistent density ensures that cuts are uniform and predictable.

4. **Rigid Structure:**

* **What it is:** The foam core provides excellent rigidity, preventing bending or warping.

* **How it Works:** The polystyrene foam is dense and resilient, providing structural support to the outer facings.

* **User Benefit:** Projects maintain their shape and form, ensuring a professional and polished appearance.

* **Demonstrates Quality:** The board’s rigidity is a testament to the quality of the materials and the manufacturing process.

5. **Versatile Applications:**

* **What it is:** Suitable for a wide range of applications, including mounting, signage, displays, and crafting.

* **How it Works:** The board’s combination of lightweight construction, smooth surface, and rigidity makes it adaptable to various uses.

* **User Benefit:** Eliminates the need for multiple materials, simplifying project planning and execution.

* **Demonstrates Quality:** Highlights the board’s adaptability and its ability to meet the diverse needs of users.

6. **Availability:**

* **What it is:** Elmer’s Foam Board is widely available at most arts and crafts stores, as well as online retailers.

* **How it Works:** Elmer’s has established a strong distribution network, ensuring that its products are easily accessible to consumers.

* **User Benefit:** Convenient and readily available, eliminating the need to search for specialized suppliers.

* **Demonstrates Quality:** Reflects Elmer’s commitment to customer service and its ability to meet the demands of the market.

7. **Cost-Effective:**

* **What it is:** Elmer’s Foam Board is relatively inexpensive compared to other rigid materials.

* **How it Works:** The polystyrene foam and paper facings are readily available and cost-effective to produce.

* **User Benefit:** Allows for budget-friendly projects without compromising on quality or appearance.

* **Demonstrates Quality:** Highlights Elmer’s ability to provide value to its customers without sacrificing product performance.

## Significant Advantages, Benefits & Real-World Value of Foam Core Board

Foam core board offers a multitude of advantages and benefits that make it an invaluable material for a wide range of applications. Let’s delve into the tangible and intangible value it provides:

* **Enhanced Visual Appeal:** The smooth, flat surface of foam core board provides an ideal canvas for displaying artwork, photographs, and graphics. Its clean lines and professional finish elevate the visual impact of any presentation.

* **Improved Durability:** While lightweight, foam core board is surprisingly durable. It resists bending, warping, and tearing, ensuring that projects maintain their integrity over time.

* **Simplified Project Planning:** The board’s versatility eliminates the need for multiple materials, streamlining the project planning process and reducing complexity.

* **Increased Creative Freedom:** The ease of cutting, painting, and decorating foam core board empowers users to explore their creativity and bring their visions to life.

* **Reduced Costs:** Foam core board is a cost-effective alternative to other rigid materials, making it an accessible option for budget-conscious projects.

Users consistently report that foam core board simplifies their creative process and enhances the quality of their finished products. Our analysis reveals these key benefits:

* **Professional-Looking Results:** The board’s smooth surface and rigid structure contribute to a polished and professional appearance, making it ideal for presentations, displays, and signage.

* **Easy Customization:** The board’s ease of cutting and decorating allows for endless customization options, empowering users to create unique and personalized projects.

* **Lightweight Portability:** The board’s lightweight nature makes it easy to transport and handle, making it ideal for projects that need to be moved frequently.

* **Long-Lasting Value:** The board’s durability ensures that projects maintain their integrity over time, providing long-lasting value and enjoyment.

## Comprehensive & Trustworthy Review of Elmer’s Foam Board

Elmer’s Foam Board is a staple in the crafting and display world, known for its versatility and ease of use. This review provides an unbiased, in-depth assessment based on practical experience and user feedback.

**User Experience & Usability:**

From a practical standpoint, Elmer’s Foam Board is incredibly easy to work with. Cutting it with a utility knife or craft knife is straightforward, resulting in clean edges. The smooth surface readily accepts paint, markers, and adhesives, allowing for a wide range of decorative techniques. Its lightweight nature makes it easy to handle and maneuver, even for large-scale projects.

**Performance & Effectiveness:**

Elmer’s Foam Board delivers on its promises of providing a rigid, flat surface for mounting and display. It effectively supports artwork, photographs, and signage, preventing sagging or warping. The board’s smooth surface ensures that images and graphics are displayed clearly and accurately. In simulated test scenarios, the board consistently maintained its shape and integrity, even under moderate stress.

**Pros:**

1. **Ease of Use:** Elmer’s Foam Board is incredibly easy to cut, decorate, and handle, making it a great choice for both beginners and experienced crafters.

2. **Versatility:** The board’s versatility makes it suitable for a wide range of applications, from mounting and display to crafting and model making.

3. **Affordability:** Elmer’s Foam Board is relatively inexpensive compared to other rigid materials, making it an accessible option for budget-conscious projects.

4. **Availability:** Elmer’s Foam Board is widely available at most arts and crafts stores, as well as online retailers.

5. **Smooth Surface:** The board’s smooth surface provides an ideal canvas for printing, painting, and adhering materials.

**Cons/Limitations:**

1. **Susceptibility to Moisture:** Elmer’s Foam Board is not water-resistant and can warp or delaminate if exposed to moisture.

2. **Limited Durability:** While durable, the board is not as strong as other rigid materials like wood or metal and can be easily damaged by impact.

3. **Potential for Dents:** The foam core is susceptible to dents and punctures if not handled carefully.

4. **Not Acid-Free:** Standard Elmer’s Foam Board is not acid-free, which can cause damage to delicate artwork over time. For archival purposes, acid-free foam core is recommended.

**Ideal User Profile:**

Elmer’s Foam Board is best suited for:

* Hobbyists and crafters looking for a versatile and easy-to-use material for their projects.

* Students and teachers needing a cost-effective material for displays and presentations.

* Businesses seeking a lightweight and affordable solution for signage and promotional materials.

**Key Alternatives:**

* **Gatorfoam:** A denser and more durable alternative to foam core board, suitable for high-impact applications.

* **Sintra PVC Board:** A rigid plastic board that is water-resistant and more durable than foam core board, ideal for outdoor signage.

**Expert Overall Verdict & Recommendation:**

Elmer’s Foam Board is a reliable and versatile material that delivers excellent value for its price. Its ease of use, versatility, and affordability make it a great choice for a wide range of projects. However, it’s important to be aware of its limitations, such as its susceptibility to moisture and potential for dents. Overall, we highly recommend Elmer’s Foam Board for hobbyists, students, and businesses seeking a cost-effective and easy-to-use solution for mounting, display, and crafting.

## Insightful Q&A Section

Here are 10 insightful questions and expert answers related to foam core board:

1. **Q: What is the best way to cut foam core board to ensure a clean, straight edge?**

* **A:** Use a sharp utility knife or craft knife with a fresh blade. Employ a metal ruler or straight edge as a guide, and make multiple light passes rather than trying to cut through the board in one go. This minimizes tearing and ensures a clean cut.

2. **Q: How can I prevent foam core board from warping or bending over time?**

* **A:** Store foam core board flat and away from direct sunlight and humidity. When mounting artwork or photos, use acid-free adhesives and back the board with a rigid material like cardboard or wood to provide additional support.

3. **Q: What type of adhesive is best for bonding materials to foam core board?**

* **A:** Acid-free spray adhesives or double-sided tape are generally recommended. Avoid using liquid glues, as they can warp the board. Test the adhesive on a small, inconspicuous area first to ensure it doesn’t damage the surface.

4. **Q: Can I paint foam core board? If so, what type of paint should I use?**

* **A:** Yes, you can paint foam core board. Acrylic paints are a good choice, as they adhere well and dry quickly. Apply thin, even coats to avoid warping the board. Consider priming the surface first with a gesso or primer designed for paper.

5. **Q: Is foam core board suitable for outdoor use?**

* **A:** Standard foam core board is not suitable for outdoor use, as it is susceptible to moisture and UV damage. However, there are specialized foam core boards with plastic facings that are more resistant to the elements.

6. **Q: How can I create a professional-looking edge on foam core board?**

* **A:** Use edge banding or trim to cover the exposed foam core. Edge banding is available in various colors and materials, and can be applied with heat or adhesive.

7. **Q: What is the difference between foam core board and Gatorfoam?**

* **A:** Gatorfoam is a denser and more durable type of foam board with a hard, resin-impregnated surface. It is more resistant to dents, scratches, and moisture than standard foam core board.

8. **Q: Can I print directly onto foam core board?**

* **A:** Yes, many print shops offer direct printing onto foam core board. This is a great option for creating professional-looking signs and displays.

9. **Q: How can I dispose of foam core board responsibly?**

* **A:** Check with your local recycling center to see if they accept foam core board. Some centers may recycle the paper facings, but the foam core is often not recyclable. As a last resort, dispose of it in the trash.

10. **Q: What are some creative uses for foam core board beyond mounting and display?**

* **A:** Foam core board can be used to create architectural models, stage props, custom shelving, and even furniture. Its lightweight nature and ease of cutting make it a versatile material for a wide range of DIY projects.

## Conclusion & Strategic Call to Action

In summary, *what is foam core board*? It’s a versatile, lightweight, and cost-effective material that’s perfect for a wide range of applications, from crafting and signage to model making and picture framing. Its smooth surface, ease of use, and rigid structure make it an ideal choice for both professionals and hobbyists. By understanding its properties and limitations, you can maximize its potential and create stunning projects that stand the test of time.

As you continue your creative journey, consider exploring the advanced techniques for working with foam core board. Mastering these techniques will allow you to unlock even greater possibilities and create truly unique and innovative projects. Our extensive testing shows that the right tools and techniques can significantly enhance the quality and durability of your foam core creations.

Share your experiences with foam core board in the comments below. We’d love to hear about your favorite projects and tips for working with this versatile material. Explore our advanced guide to mounting techniques for professional results. Contact our experts for a consultation on how to best utilize foam core board for your specific needs.