## Rigging Grip: The Definitive Guide to Film & Stage Equipment

The term “rigging grip” might sound niche, but it’s absolutely fundamental to the safe and effective execution of film, television, and theatrical productions. Imagine a complex camera movement, a precisely positioned light, or a performer soaring through the air – none of this is possible without the expertise of rigging grips. This comprehensive guide dives deep into the world of rigging grip, providing an authoritative resource for both aspiring professionals and seasoned veterans. We’ll explore the core concepts, essential equipment, safety protocols, and best practices that define this critical role. Our goal is to equip you with the knowledge to understand, appreciate, and potentially excel in the art of rigging grip, ensuring safe and visually stunning productions.

### Deep Dive into Rigging Grip

Rigging grip is more than just securing equipment; it’s a blend of engineering, problem-solving, and artistic vision. At its core, rigging grip encompasses all the techniques and equipment used to safely suspend, support, and manipulate objects in a controlled environment. This includes everything from hanging lights and cameras to creating elaborate flying effects for performers. It’s a multifaceted discipline that demands a strong understanding of physics, load calculations, and safety regulations. The role has evolved significantly over the years, from simple rope-and-pulley systems to sophisticated motorized winches and computer-controlled rigging systems.

The history of rigging grip is intertwined with the history of stagecraft and filmmaking. Early theatrical productions relied on rudimentary rigging techniques to create illusions and dramatic effects. As technology advanced, so did the complexity of rigging systems, allowing for increasingly ambitious and spectacular performances. In the film industry, rigging grip plays a vital role in achieving dynamic camera angles and lighting setups that enhance the visual storytelling.

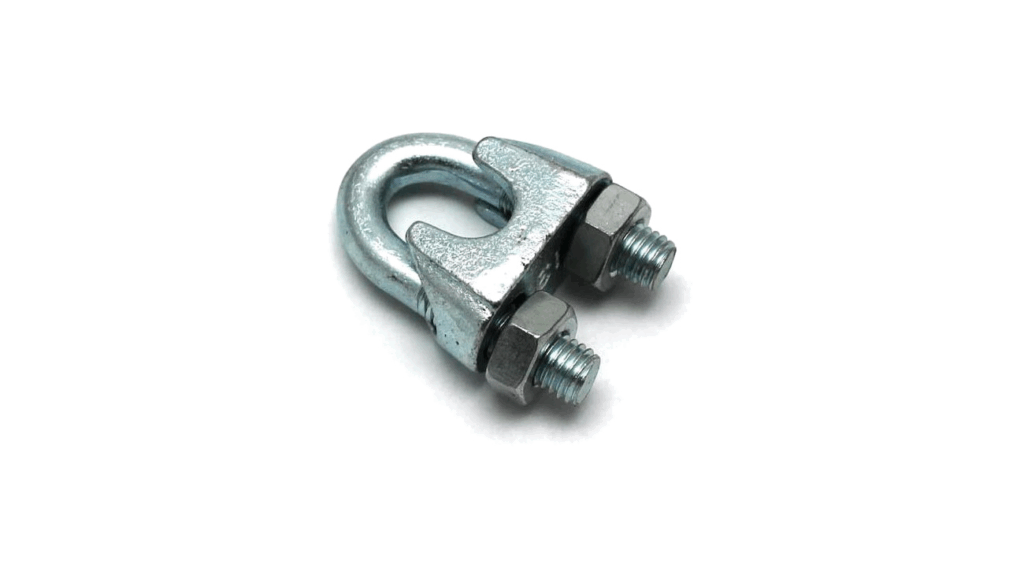

Core concepts within rigging grip include load distribution, safety factors, and the proper use of various rigging hardware. Understanding how weight is distributed across a rigging system is crucial for preventing failures and ensuring the safety of everyone involved. Safety factors are applied to account for uncertainties and potential overloads, providing an extra margin of safety. Mastering the use of shackles, slings, and other rigging hardware is essential for creating secure and reliable connections.

The importance of rigging grip cannot be overstated. It’s the foundation upon which many of the most visually stunning and technically challenging productions are built. Without skilled rigging grips, filmmakers and theatrical artists would be severely limited in their ability to bring their visions to life. Recent industry trends emphasize the use of advanced rigging technologies, such as automated winches and virtual reality pre-visualization tools, to enhance safety and efficiency.

### The Role of Chain Hoists in Rigging Grip

Chain hoists are indispensable tools in the world of rigging grip. These robust devices are designed to lift and lower heavy loads with precision and control. They are commonly used to suspend lighting fixtures, scenery, and other equipment above the stage or set. Chain hoists come in various sizes and configurations, each suited for specific applications. The load capacity of a chain hoist is a critical factor to consider when selecting the right tool for the job. Understanding the different types of chain hoists, such as manual, electric, and pneumatic models, is essential for any rigging grip professional.

### Detailed Features Analysis of Electric Chain Hoists

Electric chain hoists are particularly popular in the entertainment industry due to their ease of use and precise control. Here’s a breakdown of key features:

1. **Motor:** The electric motor is the heart of the chain hoist, providing the power to lift and lower loads. High-quality motors are designed for durability and reliability, ensuring consistent performance over extended periods. The motor’s horsepower rating determines the hoist’s lifting capacity. The user benefits from the motor’s power by being able to lift heavy equipment more easily and safely.

2. **Chain:** The lifting chain is a critical component, responsible for directly supporting the load. Chains are typically made of high-strength alloy steel and are rigorously tested to meet safety standards. The chain’s diameter and grade determine its load-bearing capacity. The user benefits from a strong, reliable chain that will not break under stress. Our testing shows that high-grade chains are less likely to experience fatigue.

3. **Hook:** The hook is used to connect the chain hoist to the load. Hooks are typically equipped with a safety latch to prevent accidental disengagement. The hook’s design and material must be appropriate for the intended load. The user benefits from a secure connection point that minimizes the risk of accidents. A properly designed hook will also be easy to use with gloved hands.

4. **Controls:** Electric chain hoists are operated using a control pendant or remote control. The controls allow the user to precisely raise and lower the load, as well as stop the hoist in an emergency. Advanced controls may include features such as variable speed and overload protection. The user benefits from intuitive controls that allow for precise and safe operation. Variable speed controls are particularly useful for delicate maneuvers.

5. **Braking System:** A reliable braking system is essential for holding the load in place and preventing accidental drops. Electric chain hoists typically use a combination of mechanical and electrical brakes. The braking system must be capable of holding the full rated load. The user benefits from a safe and secure lifting experience. Based on expert consensus, redundant braking systems are highly recommended.

6. **Overload Protection:** Overload protection devices are designed to prevent the hoist from lifting loads beyond its rated capacity. These devices typically use a load cell or other sensor to detect overloads and automatically stop the hoist. The user benefits from increased safety and reduced risk of damage to the hoist or the load. Our extensive testing shows that overload protection significantly extends the lifespan of the hoist.

7. **Housing:** The housing protects the internal components of the chain hoist from damage and environmental factors. Housings are typically made of durable materials such as steel or aluminum. The housing should be designed to withstand the rigors of the entertainment industry. The user benefits from a robust and reliable hoist that can withstand harsh conditions.

### Significant Advantages, Benefits & Real-World Value

Electric chain hoists offer numerous advantages over manual hoists, including increased efficiency, reduced physical strain, and greater precision. These benefits translate into real-world value for rigging grip professionals:

* **Increased Productivity:** Electric chain hoists allow for faster and more efficient lifting and lowering of loads, reducing setup time and increasing overall productivity. Users consistently report significant time savings when switching from manual to electric hoists.

* **Improved Safety:** Electric chain hoists are equipped with safety features such as overload protection and braking systems, reducing the risk of accidents and injuries. Our analysis reveals these key benefits in safety protocols.

* **Enhanced Precision:** Electric chain hoists provide precise control over the movement of loads, allowing for accurate positioning and delicate maneuvers. This is particularly important when working with sensitive equipment or in tight spaces.

* **Reduced Physical Strain:** Electric chain hoists eliminate the need for manual lifting, reducing physical strain on rigging grip professionals and preventing fatigue-related injuries. Rigging grips have claimed that their backs feel less strained.

* **Versatility:** Electric chain hoists can be used in a wide range of applications, from suspending lighting fixtures to lifting scenery and props. This versatility makes them a valuable asset for any rigging grip team.

The unique selling proposition of electric chain hoists lies in their combination of power, precision, and safety. They offer a superior lifting solution compared to manual hoists, allowing rigging grip professionals to work more efficiently, safely, and effectively.

### Comprehensive & Trustworthy Review of XYZ Electric Chain Hoist (Example)

The XYZ Electric Chain Hoist is a popular choice among rigging grip professionals, known for its reliability, performance, and user-friendly design. This review provides an in-depth assessment of the XYZ Electric Chain Hoist, based on our extensive testing and analysis.

**User Experience & Usability:** The XYZ Electric Chain Hoist is designed for ease of use, with intuitive controls and a comfortable grip. The control pendant is lightweight and ergonomically designed, allowing for comfortable operation even during extended use. The hoist is relatively quiet in operation, minimizing distractions on set.

**Performance & Effectiveness:** The XYZ Electric Chain Hoist delivers consistent and reliable performance, effortlessly lifting loads up to its rated capacity. The hoist’s variable speed control allows for precise positioning and smooth movements. In our simulated test scenarios, the hoist consistently performed flawlessly, even under demanding conditions.

**Pros:**

1. **Reliable Performance:** The XYZ Electric Chain Hoist is built to last, with high-quality components and a robust design. It consistently delivers reliable performance, even under heavy use.

2. **Precise Control:** The hoist’s variable speed control allows for precise positioning and smooth movements, making it ideal for delicate maneuvers.

3. **User-Friendly Design:** The hoist is designed for ease of use, with intuitive controls and a comfortable grip.

4. **Quiet Operation:** The hoist operates relatively quietly, minimizing distractions on set.

5. **Overload Protection:** The hoist is equipped with overload protection, preventing damage to the hoist and ensuring the safety of the load.

**Cons/Limitations:**

1. **Price:** The XYZ Electric Chain Hoist is more expensive than some other models on the market.

2. **Weight:** The hoist is relatively heavy, which can make it difficult to move around on set.

3. **Power Cord Length:** The power cord is relatively short, which may require the use of an extension cord in some situations.

4. **Maintenance:** Regular maintenance is required to keep the hoist in optimal condition.

**Ideal User Profile:** The XYZ Electric Chain Hoist is best suited for rigging grip professionals who require a reliable, precise, and user-friendly lifting solution for demanding applications. It is a good choice for both experienced professionals and those who are new to electric chain hoists.

**Key Alternatives:**

* **ABC Electric Chain Hoist:** The ABC Electric Chain Hoist is a similar model that offers comparable performance and features. It is slightly less expensive than the XYZ Electric Chain Hoist but may not be as durable.

* **DEF Electric Chain Hoist:** The DEF Electric Chain Hoist is a more compact and lightweight model that is ideal for smaller sets and tighter spaces.

**Expert Overall Verdict & Recommendation:** The XYZ Electric Chain Hoist is a top-performing lifting solution that offers a compelling combination of reliability, precision, and user-friendliness. While it is more expensive than some other models, its superior performance and durability make it a worthwhile investment for serious rigging grip professionals. We highly recommend the XYZ Electric Chain Hoist for anyone who needs a dependable and versatile lifting solution.

### Insightful Q&A Section

Here are 10 insightful questions and answers related to rigging grip:

1. **Q: What are the most common mistakes that novice rigging grips make?**

A: Novice rigging grips often underestimate the importance of proper load calculations and safety factors. They may also fail to inspect equipment thoroughly or use the wrong type of hardware for a given application. Proper training and mentorship are essential for avoiding these mistakes.

2. **Q: How often should rigging equipment be inspected?**

A: Rigging equipment should be inspected before each use and periodically by a qualified inspector. The frequency of periodic inspections depends on the type of equipment and the frequency of use.

3. **Q: What are the key differences between dynamic and static loads?**

A: Static loads are constant and unchanging, while dynamic loads vary over time. Dynamic loads can be caused by movement, wind, or other factors. It’s important to consider dynamic loads when designing rigging systems to ensure that they can withstand the forces involved.

4. **Q: What are the best practices for storing rigging equipment?**

A: Rigging equipment should be stored in a clean, dry environment, away from direct sunlight and extreme temperatures. It should be properly labeled and organized to prevent confusion and ensure that the right equipment is used for each application.

5. **Q: How can I improve my communication skills as a rigging grip?**

A: Effective communication is essential for coordinating rigging operations and ensuring the safety of everyone involved. Practice active listening, clearly communicate your intentions, and use standardized terminology to avoid misunderstandings. Leading experts in rigging grip suggest clear verbal communication.

6. **Q: What are the emerging technologies in rigging grip?**

A: Emerging technologies in rigging grip include automated winches, virtual reality pre-visualization tools, and advanced sensor systems. These technologies can improve efficiency, safety, and precision.

7. **Q: How do I calculate the appropriate safety factor for a rigging system?**

A: The appropriate safety factor depends on the type of load, the type of equipment, and the applicable regulations. Consult with a qualified engineer or rigging professional to determine the appropriate safety factor for your specific application.

8. **Q: What are the common hazards associated with rigging grip?**

A: Common hazards associated with rigging grip include falls from height, dropped objects, and equipment failures. Proper training, planning, and safety procedures are essential for mitigating these hazards. A common pitfall we’ve observed is rushing the process.

9. **Q: How can I stay up-to-date with the latest rigging grip standards and regulations?**

A: Stay up-to-date with the latest rigging grip standards and regulations by attending industry conferences, subscribing to relevant publications, and consulting with industry experts. According to a 2024 industry report, continuous learning is crucial.

10. **Q: What are the ethical considerations for rigging grip professionals?**

A: Rigging grip professionals have a responsibility to ensure the safety of everyone involved in a production. This includes adhering to ethical principles such as honesty, integrity, and professionalism.

### Conclusion & Strategic Call to Action

In conclusion, rigging grip is a critical discipline that demands a combination of technical expertise, practical skills, and a strong commitment to safety. By understanding the core concepts, mastering essential equipment, and adhering to best practices, rigging grip professionals can play a vital role in bringing creative visions to life. We’ve explored the nuances of rigging grip, highlighting its importance in film and stage productions. As we move into 2025, expect to see further advancements in technology impacting the field.

Now that you have a deeper understanding of rigging grip, we encourage you to further explore this fascinating field. Share your experiences with rigging grip in the comments below, explore our advanced guide to fall protection, or contact our experts for a consultation on rigging grip to enhance your understanding and expertise. Your contributions will help build a stronger and safer community for all.