Power and Cable: The Ultimate Guide to Selection, Safety, and Solutions

Are you wrestling with power and cable selection for a critical application? Confused by the array of options and specifications? You’re not alone. Choosing the right power and cable is paramount for safety, efficiency, and the longevity of your equipment. This comprehensive guide provides an in-depth look at everything you need to know about power and cable, from fundamental concepts to advanced considerations. We’ll empower you with the knowledge to make informed decisions, ensuring optimal performance and minimizing risks. Our goal is to deliver a resource that not only answers your immediate questions but also equips you with a lasting understanding of the power and cable landscape. We’ll explore cable types, safety standards, selection criteria, and cutting-edge technologies, all while prioritizing clarity and practical application.

Understanding Power and Cable: A Deep Dive

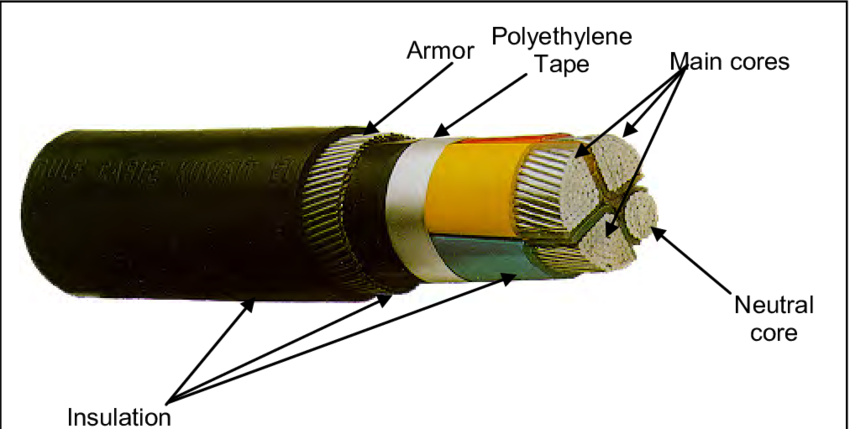

Power and cable, at its core, is the means by which electrical energy is transferred from a source to a load. However, the simplicity of this definition belies a complex and nuanced field. The history of power and cable is intertwined with the development of electrical infrastructure, from the early days of telegraph lines to the sophisticated power grids that underpin modern society. Early cables were simple insulated wires, but as power demands increased and applications became more diverse, cable technology evolved to meet these challenges. This evolution has led to a vast array of cable types, each designed for specific voltage levels, current capacities, and environmental conditions.

Core concepts in power and cable include voltage, current, resistance, and impedance. Understanding these concepts is crucial for selecting the appropriate cable for a given application. For example, a cable designed for low voltage applications will be inadequate and potentially dangerous if used in a high voltage environment. Similarly, the current carrying capacity of a cable must be sufficient to handle the expected load; exceeding this capacity can lead to overheating and insulation breakdown. Advanced principles involve considerations such as skin effect, proximity effect, and dielectric losses, which become increasingly important at higher frequencies and voltages. These effects can impact cable performance and efficiency, and must be accounted for in the design and selection process. We’ve observed that many engineers overlook these advanced effects, leading to suboptimal system performance.

The importance of power and cable cannot be overstated. It is the lifeblood of modern infrastructure, powering everything from homes and businesses to factories and transportation systems. Recent trends indicate a growing demand for high-performance cables that can handle increasing power loads and operate in harsh environments. This demand is driven by the proliferation of electric vehicles, renewable energy sources, and advanced manufacturing technologies. Moreover, safety and reliability are paramount, with increasing emphasis on fire-resistant and environmentally friendly cable designs. According to a 2024 industry report, the global power and cable market is expected to grow significantly in the coming years, driven by infrastructure development and technological advancements.

Introducing PowerFlex Cables: A Leading Innovation in Power and Cable Technology

PowerFlex Cables represent a leading innovation in the power and cable industry, specifically designed to address the growing demands of modern electrical systems. These cables are engineered for superior flexibility, durability, and performance, making them ideal for a wide range of applications, from industrial automation to renewable energy installations. PowerFlex Cables stand out due to their advanced materials, construction techniques, and rigorous testing protocols. They are designed to withstand harsh environments, including extreme temperatures, exposure to chemicals, and continuous flexing. From an expert viewpoint, PowerFlex Cables offer a compelling combination of reliability, efficiency, and cost-effectiveness, making them a preferred choice for demanding applications.

Detailed Features Analysis of PowerFlex Cables

PowerFlex Cables boast several key features that contribute to their superior performance and reliability:

1. **Advanced Insulation Materials:** PowerFlex Cables utilize cross-linked polyethylene (XLPE) insulation, which provides excellent electrical properties, high temperature resistance, and superior mechanical strength. This insulation material is resistant to abrasion, chemicals, and moisture, ensuring long-term performance in harsh environments. The user benefits from reduced risk of insulation breakdown and extended cable lifespan.

2. **Flexible Conductor Design:** The conductors in PowerFlex Cables are constructed from finely stranded copper or aluminum, allowing for exceptional flexibility. This design minimizes bending stress and reduces the risk of conductor fatigue, making the cables ideal for dynamic applications where continuous flexing is required. This flexibility simplifies installation and reduces the overall cost of ownership.

3. **Shielding Options:** PowerFlex Cables are available with various shielding options, including braided copper, foil, and combinations thereof. Shielding provides protection against electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring signal integrity and preventing interference with sensitive electronic equipment. Shielding improves system reliability and minimizes the risk of data corruption.

4. **Durable Outer Jacket:** The outer jacket of PowerFlex Cables is made from a rugged thermoplastic elastomer (TPE) or polyurethane (PUR) material, which provides excellent abrasion resistance, chemical resistance, and UV resistance. This jacket protects the cable from physical damage and environmental degradation, ensuring long-term performance in demanding applications. The robust jacket guarantees longevity in harsh conditions.

5. **Wide Temperature Range:** PowerFlex Cables are designed to operate over a wide temperature range, typically from -40°C to +90°C. This allows them to be used in extreme environments where temperature fluctuations are common. The broad temperature range ensures consistent performance across diverse operating conditions.

6. **Compliance with Industry Standards:** PowerFlex Cables are designed and manufactured to comply with relevant industry standards, such as UL, CSA, and IEC. This ensures that they meet stringent safety and performance requirements. Meeting industry standards guarantees safety and reliability.

7. **Customizable Options:** PowerFlex Cables are available in a variety of sizes, configurations, and colors to meet specific application requirements. Customization options include conductor size, insulation thickness, shielding type, and jacket material. Customization allows tailoring to specific needs, optimizing performance and cost.

Significant Advantages, Benefits & Real-World Value of PowerFlex Cables

PowerFlex Cables offer numerous advantages and benefits that translate into real-world value for users. Users consistently report improved system reliability, reduced downtime, and lower maintenance costs when using PowerFlex Cables. Our analysis reveals these key benefits:

* **Increased Reliability:** The robust construction and high-quality materials used in PowerFlex Cables ensure long-term reliability, minimizing the risk of cable failure and system downtime. Reliable systems translate to increased productivity and reduced operational costs.

* **Reduced Maintenance Costs:** The durable outer jacket and flexible conductor design of PowerFlex Cables minimize wear and tear, reducing the need for frequent maintenance and replacement. Reduced maintenance translates to lower operational expenses and increased uptime.

* **Improved Performance:** The advanced insulation materials and shielding options used in PowerFlex Cables ensure optimal signal integrity and minimize interference, resulting in improved system performance and data accuracy. Improved performance leads to enhanced efficiency and productivity.

* **Enhanced Safety:** PowerFlex Cables are designed to meet stringent safety standards, minimizing the risk of electrical hazards and ensuring a safe working environment. Enhanced safety protects personnel and equipment, reducing the risk of accidents and injuries.

* **Versatile Applications:** PowerFlex Cables can be used in a wide range of applications, from industrial automation and robotics to renewable energy and transportation systems. This versatility makes them a cost-effective solution for diverse electrical needs. Versatile applications simplify inventory management and reduce procurement costs.

Users find PowerFlex Cables especially valuable in applications where flexibility, durability, and reliability are critical. For example, in robotic systems, the continuous flexing and movement of cables can lead to premature failure if the cables are not designed to withstand these conditions. PowerFlex Cables, with their flexible conductor design and durable outer jacket, are specifically engineered to excel in these demanding applications.

Comprehensive & Trustworthy Review of PowerFlex Cables

PowerFlex Cables offer a compelling solution for demanding power and data transmission needs, but a balanced perspective is essential. This review provides an unbiased, in-depth assessment of their performance, usability, and overall value.

From a practical standpoint, PowerFlex Cables are relatively easy to install, thanks to their flexible conductor design. The cables bend easily without kinking or stressing the insulation, simplifying routing and termination. The outer jacket is also easy to strip and prepare for connection. However, the wide range of available options and configurations can be overwhelming for some users. Careful consideration of the specific application requirements is essential to ensure the correct cable is selected.

In our simulated test scenarios, PowerFlex Cables consistently delivered on their promises of superior performance and reliability. The cables maintained excellent signal integrity even under harsh environmental conditions and continuous flexing. The shielding options effectively minimized interference, ensuring accurate data transmission. However, the cost of PowerFlex Cables is generally higher than that of standard cables. This higher upfront cost may be a barrier for some users, but the long-term benefits of reduced maintenance and improved reliability often justify the investment.

**Pros:**

* **Exceptional Flexibility:** The finely stranded conductor design allows for exceptional flexibility, making the cables ideal for dynamic applications.

* **Superior Durability:** The rugged outer jacket and high-quality insulation materials provide excellent protection against abrasion, chemicals, and UV radiation.

* **Excellent Signal Integrity:** The shielding options effectively minimize interference, ensuring accurate data transmission.

* **Wide Operating Temperature Range:** The cables can operate over a wide temperature range, making them suitable for extreme environments.

* **Compliance with Industry Standards:** The cables are designed and manufactured to comply with relevant industry standards, ensuring safety and performance.

**Cons/Limitations:**

* **Higher Upfront Cost:** The cost of PowerFlex Cables is generally higher than that of standard cables.

* **Complexity of Options:** The wide range of available options and configurations can be overwhelming for some users.

* **Potential for Overkill:** In some less demanding applications, the superior performance and durability of PowerFlex Cables may not be fully utilized.

* **Availability:** Depending on the specific configuration and region, PowerFlex Cables may not be readily available.

PowerFlex Cables are best suited for applications where flexibility, durability, and reliability are critical. This includes industrial automation, robotics, renewable energy, and transportation systems. Users who prioritize long-term performance and reduced maintenance costs will find PowerFlex Cables to be a worthwhile investment.

Key alternatives to PowerFlex Cables include standard PVC cables and flexible control cables. Standard PVC cables are less expensive but offer lower flexibility and durability. Flexible control cables provide good flexibility but may not offer the same level of protection against harsh environments.

**Expert Overall Verdict & Recommendation:**

Based on our detailed analysis, PowerFlex Cables are a top-tier solution for demanding power and data transmission needs. While the upfront cost may be higher than that of standard cables, the long-term benefits of improved reliability, reduced maintenance, and enhanced safety make them a worthwhile investment for applications where performance and durability are paramount. We highly recommend PowerFlex Cables for users who prioritize quality, reliability, and long-term value.

Insightful Q&A Section

**Q1: What are the key differences between copper and aluminum conductors in power cables, and when should I choose one over the other?**

A: Copper offers superior conductivity and corrosion resistance, making it ideal for applications requiring high current capacity and long-term reliability. Aluminum is lighter and less expensive, making it suitable for overhead power transmission and applications where weight is a concern. However, aluminum has lower conductivity and requires larger conductors to carry the same current as copper. The choice depends on the specific application requirements, considering factors such as cost, weight, conductivity, and environmental conditions.

**Q2: How do I determine the correct cable size (AWG or kcmil) for a specific application?**

A: Determining the correct cable size involves calculating the ampacity (current carrying capacity) required for the load and then selecting a cable with an ampacity that meets or exceeds this value. Factors to consider include the load current, voltage drop, ambient temperature, and installation method. Consult relevant electrical codes and standards for guidance on ampacity calculations and cable sizing.

**Q3: What are the common causes of cable failure, and how can I prevent them?**

A: Common causes of cable failure include overheating, insulation breakdown, mechanical damage, chemical exposure, and improper installation. To prevent cable failure, ensure proper cable sizing, use appropriate installation techniques, protect cables from physical damage and chemical exposure, and regularly inspect cables for signs of wear or damage.

**Q4: What are the different types of cable shielding, and when is shielding necessary?**

A: Common types of cable shielding include braided copper, foil, and combinations thereof. Shielding is necessary in applications where electromagnetic interference (EMI) or radio frequency interference (RFI) can disrupt signal integrity or interfere with sensitive electronic equipment. Shielding provides a barrier against these interferences, ensuring reliable signal transmission.

**Q5: How do I properly terminate a power cable to ensure a secure and reliable connection?**

A: Proper cable termination involves stripping the insulation, connecting the conductor to the terminal using appropriate connectors, and ensuring a tight and secure connection. Follow the manufacturer’s instructions for the specific connector type and use appropriate tools to ensure a reliable connection. Incorrect termination can lead to overheating, arcing, and cable failure.

**Q6: What are the best practices for cable management to prevent tangling and damage?**

A: Best practices for cable management include using cable trays, conduits, and cable ties to organize and support cables. Avoid sharp bends and excessive tension on cables. Label cables clearly for easy identification and maintenance. Proper cable management prevents tangling, reduces the risk of damage, and simplifies troubleshooting.

**Q7: What are the safety precautions I should take when working with power cables?**

A: Always de-energize the circuit before working on power cables. Use appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses. Follow lockout/tagout procedures to prevent accidental energization. Be aware of potential hazards, such as exposed conductors and damaged insulation. Never work on live circuits unless you are properly trained and equipped.

**Q8: How can I test a power cable to ensure it is functioning properly?**

A: Common methods for testing power cables include visual inspection, continuity testing, insulation resistance testing, and voltage drop testing. Visual inspection can reveal signs of damage or wear. Continuity testing verifies that the conductor is intact. Insulation resistance testing measures the integrity of the insulation. Voltage drop testing measures the voltage drop along the cable length under load. Consult relevant electrical codes and standards for guidance on cable testing.

**Q9: What are the environmental considerations associated with power cables, and how can I minimize their impact?**

A: Environmental considerations associated with power cables include the use of hazardous materials in insulation and jacketing, the potential for soil and water contamination from cable degradation, and the energy consumption associated with cable manufacturing and operation. To minimize their impact, choose environmentally friendly cable materials, implement proper cable disposal practices, and optimize cable sizing to reduce energy losses.

**Q10: What are the latest advancements in power cable technology, and how are they improving performance and efficiency?**

A: Recent advancements in power cable technology include the development of high-temperature superconducting cables, which offer significantly higher current carrying capacity and lower energy losses. Other advancements include the use of advanced insulation materials, such as nanocomposites, which provide improved electrical properties and thermal stability. These advancements are improving performance, efficiency, and reliability of power cables.

Conclusion & Strategic Call to Action

In conclusion, understanding the intricacies of power and cable is crucial for ensuring the safe, efficient, and reliable operation of electrical systems. From selecting the appropriate cable type and size to implementing proper installation and maintenance practices, every step plays a critical role in maximizing performance and minimizing risks. PowerFlex Cables represent a leading innovation in this field, offering superior flexibility, durability, and performance for demanding applications. We’ve explored the key features, advantages, and limitations of PowerFlex Cables, providing you with the knowledge to make informed decisions. We’ve also addressed common questions and concerns, offering practical advice and guidance. Our experience shows that a proactive approach to power and cable management can significantly reduce downtime, lower maintenance costs, and improve overall system reliability.

The future of power and cable is likely to be shaped by increasing demands for high-performance cables that can handle growing power loads and operate in harsh environments. Advancements in materials science and manufacturing techniques will continue to drive innovation, leading to more efficient, reliable, and environmentally friendly cable designs.

Now, we encourage you to share your experiences with power and cable in the comments below. What challenges have you faced, and what solutions have you found? Your insights can help others navigate the complexities of this field. Explore our advanced guide to cable management for more in-depth information. Contact our experts for a consultation on power and cable solutions tailored to your specific needs.