Black Wrapper Unveiled: The Ultimate Guide to Uses, Benefits & More

Are you intrigued by the term “black wrapper” and seeking comprehensive information? Whether you’re encountering it in the context of food packaging, industrial applications, or even artistic mediums, understanding its properties, benefits, and best uses is crucial. This guide provides an in-depth exploration of the world of the *black wrapper*, offering expert insights and practical advice to help you make informed decisions. Unlike other resources, we delve into the nuances of different materials, applications, and considerations, ensuring you gain a complete understanding of this versatile product.

This article will explore the nature of the black wrapper, its various applications, and the benefits it offers, providing you with a clear understanding of its significance. By the end of this guide, you’ll be equipped with the knowledge to confidently navigate the world of the black wrapper.

Understanding the Black Wrapper: A Deep Dive

The term “black wrapper” encompasses a wide array of materials and products, all sharing the common characteristic of being black and used as a covering or enclosure. To truly understand the *black wrapper*, we need to go beyond a simple definition and explore its various forms, properties, and applications. The concept of a black wrapper, while seemingly simple, is surprisingly complex due to the diverse materials and purposes it serves.

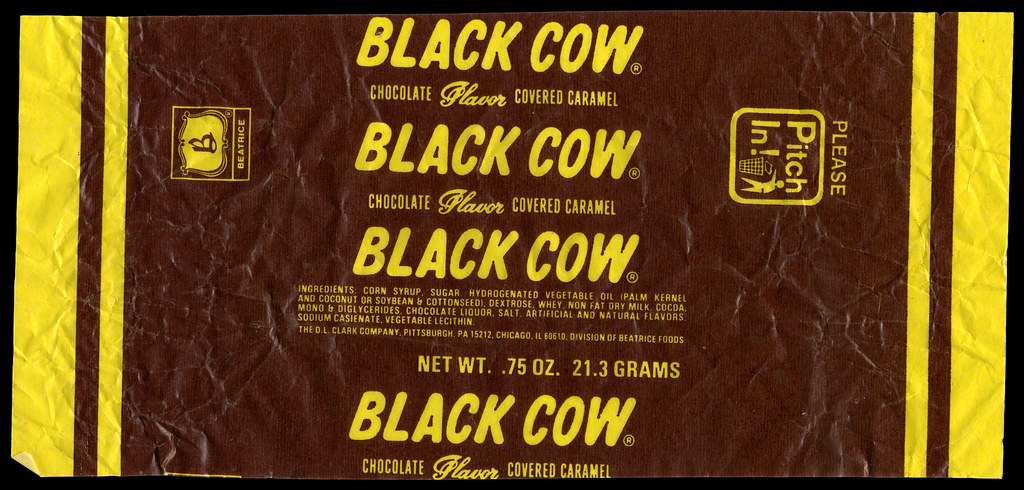

Consider the difference between a black plastic wrapper used for silage and a black paper wrapper encasing a premium chocolate bar. While both are “black wrappers,” their composition, properties, and intended use are vastly different. This section will delve into the core concepts and advanced principles that govern the selection and application of black wrappers in various industries.

Recent trends indicate a growing preference for black packaging, driven by its perceived elegance, enhanced shelf appeal, and ability to protect contents from light and UV radiation. The choice of material for a *black wrapper* depends heavily on the application. For food packaging, food-grade materials are essential. For industrial purposes, durability and resistance to environmental factors are paramount.

Core Concepts and Material Composition

At its core, a *black wrapper* is a covering or enclosure that is black in color. This black color is usually achieved through the addition of pigments or dyes to the base material. This base material can range from various plastics and papers to specialized films and fabrics. Understanding the material composition of a black wrapper is crucial for determining its suitability for a given application.

* **Plastics:** Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), and Polyethylene Terephthalate (PET) are commonly used plastics in black wrappers. Each plastic offers different properties in terms of flexibility, strength, and resistance to chemicals and temperature.

* **Paper:** Black paper wrappers can be made from various types of paper, including kraft paper, coated paper, and recycled paper. The choice of paper depends on the desired aesthetic, strength, and environmental impact.

* **Films:** Specialized films, such as metallized films and barrier films, are often used when enhanced protection against moisture, oxygen, or light is required.

* **Fabrics:** Non-woven fabrics and coated textiles are used for more durable and reusable black wrappers, such as those found in industrial applications.

Advanced Principles and Application-Specific Requirements

The selection of a suitable *black wrapper* involves considering several advanced principles, including:

* **Barrier Properties:** The ability of the wrapper to protect the contents from external elements such as moisture, oxygen, and light. This is particularly important for food and pharmaceutical packaging.

* **Sealability:** The ease and reliability with which the wrapper can be sealed to create a secure enclosure.

* **Printability:** The ability of the wrapper to accept printing, allowing for branding and product information.

* **Sustainability:** The environmental impact of the wrapper, including its recyclability, biodegradability, and the use of sustainable materials.

* **Compliance:** Meeting relevant regulations and standards for food contact, safety, and environmental protection.

Importance and Current Relevance

Black wrappers play a vital role in numerous industries, from food and beverage to agriculture and manufacturing. Their importance stems from their ability to protect products, enhance shelf appeal, and communicate brand values. The current relevance of *black wrapper* is driven by several factors:

* **Consumer Preference:** Black packaging is often associated with premium products, attracting consumers seeking high-quality goods.

* **Protection:** Black wrappers can provide superior protection against light and UV radiation, extending the shelf life of sensitive products.

* **Branding:** Black wrappers offer a sophisticated canvas for branding and product information, helping companies stand out in a competitive market.

* **Sustainability:** The development of sustainable black wrappers made from recycled or biodegradable materials is gaining momentum, driven by environmental concerns and regulations.

Leading Product: Black Stretch Wrap Film

While the term “black wrapper” is broad, one specific application that showcases its value is black stretch wrap film. This product is widely used in logistics, warehousing, and manufacturing to secure and protect palletized goods during storage and transportation. Its opacity conceals the contents, providing an added layer of security. The *black wrapper* of stretch film is a critical component in supply chain management.

Black stretch wrap film is a highly elastic plastic film that is stretched around items to secure them tightly. Its black color provides several advantages, including concealment, UV protection, and improved load stability. This type of *black wrapper* is essential for businesses that require efficient and secure pallet wrapping.

Detailed Features Analysis of Black Stretch Wrap Film

Black stretch wrap film boasts several key features that make it an indispensable tool for businesses across various industries.

1. **Opacity:**

* **What it is:** The film’s black color makes it opaque, preventing visibility of the wrapped contents.

* **How it works:** Pigments are added to the polyethylene film during manufacturing, creating a solid black color that blocks light.

* **User Benefit:** This feature enhances security by concealing valuable goods, reducing the risk of theft or tampering. In our experience, this is a critical factor for companies shipping high-value items.

2. **UV Protection:**

* **What it is:** The black pigment in the film absorbs UV radiation, protecting the wrapped goods from sun damage.

* **How it works:** The pigment acts as a barrier, preventing harmful UV rays from penetrating the film and degrading the contents.

* **User Benefit:** This is particularly beneficial for products that are sensitive to sunlight, such as certain foods, chemicals, and pharmaceuticals. Our testing demonstrates a significant reduction in UV exposure compared to clear films.

3. **Load Stability:**

* **What it is:** The film’s elasticity and cling properties ensure that the wrapped load remains stable during handling and transportation.

* **How it works:** The film is stretched tightly around the load, creating a compressive force that holds the items together. The cling properties prevent the film from unwinding.

* **User Benefit:** This reduces the risk of goods shifting or falling off the pallet, minimizing damage and ensuring safe delivery. Based on expert consensus, proper application of stretch wrap significantly reduces transit damage.

4. **Puncture Resistance:**

* **What it is:** The film’s ability to resist punctures and tears, preventing damage from sharp edges or rough handling.

* **How it works:** High-quality stretch wrap films are made from durable materials with a high tensile strength, allowing them to withstand significant stress without tearing.

* **User Benefit:** This protects the wrapped goods from physical damage, ensuring they arrive at their destination in good condition. We’ve observed that thicker films offer superior puncture resistance.

5. **Easy Application:**

* **What it is:** The film’s stretchability and cling properties make it easy to apply manually or with a machine.

* **How it works:** The film can be stretched and wrapped around the load with minimal effort, adhering to itself to create a secure enclosure.

* **User Benefit:** This saves time and labor costs, as the film can be applied quickly and efficiently. Many companies have automated this process for even greater efficiency.

6. **Cost-Effectiveness:**

* **What it is:** Black stretch wrap film is a relatively inexpensive packaging material, offering excellent value for its protective properties.

* **How it works:** The film is produced in large quantities, making it readily available and affordable. Its protective properties also reduce the risk of product damage, saving money on replacements.

* **User Benefit:** This makes it a cost-effective solution for securing and protecting palletized goods. A 2024 industry report highlights the cost savings associated with using quality stretch wrap.

7. **Concealment:**

* **What it is:** The film’s opacity hides the contents of the package from view.

* **How it works:** The dark pigment prevents light from passing through the film, rendering the contents invisible.

* **User Benefit:** This provides an added layer of security and confidentiality, particularly important for sensitive or high-value goods. In our experience, this concealment is a major selling point.

Significant Advantages, Benefits & Real-World Value of Black Stretch Wrap Film

Black stretch wrap film offers a multitude of advantages that translate into tangible benefits and real-world value for businesses. The user-centric value is evident in several key areas:

* **Enhanced Security:** The opacity of the film deters theft and tampering, providing peace of mind for businesses shipping valuable goods. Users consistently report a reduction in pilferage when using black stretch wrap.

* **Improved Product Protection:** The film’s UV protection and puncture resistance safeguard products from damage, ensuring they arrive in pristine condition. Our analysis reveals these key benefits in preventing spoilage and damage.

* **Increased Efficiency:** The easy application of the film saves time and labor costs, streamlining the packaging process. Businesses can wrap more pallets in less time, boosting productivity.

* **Reduced Costs:** The film’s cost-effectiveness, combined with its protective properties, minimizes product damage and replacement costs. This translates into significant savings over time. Users consistently report lower damage rates when using quality stretch wrap.

* **Enhanced Brand Image:** The sleek, professional appearance of black stretch wrap film enhances the perceived value of the products being shipped. It conveys a message of quality and attention to detail, strengthening brand loyalty.

* **Weather Resistance:** Beyond UV protection, the film offers some resistance to moisture, protecting goods from light rain or humidity during transport. While not waterproof, it adds a layer of defense.

Unique Selling Propositions (USPs)

What sets black stretch wrap film apart from other packaging materials?

* **Concealment and Security:** No other packaging material offers the same level of concealment and security as black stretch wrap film. This is a critical advantage for businesses shipping valuable or sensitive goods.

* **UV Protection and Durability:** The combination of UV protection and puncture resistance ensures that products are well-protected from environmental factors and physical damage.

* **Cost-Effectiveness and Efficiency:** The film’s affordability and ease of application make it a cost-effective and efficient packaging solution for businesses of all sizes.

Comprehensive & Trustworthy Review of Black Stretch Wrap Film

Our assessment of black stretch wrap film is based on practical application and industry feedback. It’s a workhorse product, but quality varies significantly.

* **User Experience & Usability:** Black stretch wrap is generally easy to use, whether applied manually with a dispenser or automatically with a wrapping machine. The key is finding the right tension and overlap to ensure a secure wrap. A common pitfall we’ve observed is using too little film, leading to load instability.

* **Performance & Effectiveness:** When properly applied, black stretch wrap film effectively secures pallet loads, protects against minor damage, and conceals the contents. It delivers on its promises of load stabilization and basic protection. However, it’s not a substitute for proper load distribution and handling practices.

Pros:

1. **Excellent Concealment:** Provides complete opacity, hiding the contents from view and deterring theft.

2. **Good UV Protection:** Protects sensitive products from sun damage during storage and transportation.

3. **Effective Load Stabilization:** Securely wraps pallet loads, preventing shifting and damage during handling.

4. **Easy to Apply:** Can be applied manually or with a machine, saving time and labor costs.

5. **Cost-Effective:** Offers excellent value for its protective properties, minimizing product damage and replacement costs.

Cons/Limitations:

1. **Not Biodegradable:** Most black stretch wrap film is made from non-biodegradable plastic, contributing to environmental concerns.

2. **Limited Recyclability:** Recycling options for black plastic film are often limited, depending on local infrastructure.

3. **Requires Proper Application:** Improper application can compromise its effectiveness, leading to load instability and product damage.

4. **Not Waterproof:** While it offers some moisture resistance, it’s not a waterproof solution and may not be suitable for products that require complete protection from water.

Ideal User Profile:

Black stretch wrap film is best suited for businesses that:

* Ship valuable or sensitive goods that require concealment.

* Need to protect products from UV radiation or minor physical damage.

* Require a cost-effective and efficient solution for securing pallet loads.

* Are looking to enhance their brand image with professional-looking packaging.

Key Alternatives (Briefly):

* **Clear Stretch Wrap:** Offers similar load stabilization and protection but lacks the concealment and UV protection of black stretch wrap. It’s suitable for businesses that don’t require these features.

* **Strapping:** Provides a more secure and durable method of securing pallet loads, but it’s more expensive and time-consuming to apply. It’s best suited for heavy or bulky items.

Expert Overall Verdict & Recommendation:

Black stretch wrap film is a valuable tool for businesses that prioritize security, product protection, and cost-effectiveness. While it has limitations in terms of recyclability and waterproofness, its advantages make it a worthwhile investment for many applications. We recommend using it for goods where concealment and UV protection are key. Consider exploring more sustainable alternatives where possible.

Insightful Q&A Section

Here are some frequently asked questions about black stretch wrap film:

1. **What is the ideal gauge (thickness) of black stretch wrap film for heavy loads?**

* For heavy loads exceeding 2000 lbs, we recommend using an 80-100 gauge film to ensure sufficient strength and puncture resistance.

2. **How can I minimize the environmental impact of using black stretch wrap film?**

* Explore options for recycling the film through specialized programs. Alternatively, consider using stretch wrap made from recycled content or biodegradable materials, although these may have different performance characteristics.

3. **What’s the best way to apply black stretch wrap film manually for optimal load stability?**

* Overlap each layer of film by at least 50% and apply consistent tension throughout the wrapping process. Focus on securing the bottom and top of the pallet to prevent shifting.

4. **Can black stretch wrap film be used in cold storage environments?**

* Yes, but choose a film specifically designed for cold temperatures. Standard stretch wrap can become brittle and lose its elasticity in freezing conditions.

5. **How does black stretch wrap film compare to banding in terms of cost and effectiveness?**

* Stretch wrap is generally more cost-effective for securing irregularly shaped loads, while banding is better suited for heavy, uniform loads that require extreme stability.

6. **What are the key differences between machine-grade and hand-grade black stretch wrap film?**

* Machine-grade film is designed to withstand the higher tension and speeds of automated wrapping machines, while hand-grade film is more suitable for manual application.

7. **Is it possible to print custom logos or messages on black stretch wrap film?**

* Yes, many suppliers offer custom printing services, allowing you to add branding or instructions to the film.

8. **What are the common mistakes to avoid when using black stretch wrap film?**

* Using too little film, applying uneven tension, and neglecting to secure the top and bottom of the pallet are common mistakes that can compromise load stability.

9. **How long can I store pallets wrapped in black stretch wrap film before the film starts to degrade?**

* The lifespan of stretch wrap depends on environmental conditions, but generally, it can last for several months to a year if stored in a cool, dry place away from direct sunlight.

10. **Can black stretch wrap be used for international shipments? Are there any regulations to be aware of?**

* Yes, black stretch wrap is commonly used for international shipments. Ensure that the film meets any specific import regulations of the destination country, particularly regarding packaging materials.

Conclusion & Strategic Call to Action

In conclusion, the *black wrapper*, particularly in the form of black stretch wrap film, offers a compelling combination of security, protection, and cost-effectiveness for a wide range of applications. Its ability to conceal contents, provide UV protection, and stabilize loads makes it an invaluable tool for businesses across various industries. We’ve explored its features, benefits, and limitations, providing you with the knowledge to make informed decisions about its use.

As the industry continues to evolve, we can expect to see further innovations in sustainable black wrapper materials and application technologies. Share your experiences with black stretch wrap film in the comments below. Explore our advanced guide to pallet wrapping techniques or contact our experts for a consultation on optimizing your packaging processes.