Target Allen Keys: The Ultimate Guide to Selection, Use & Maintenance

Are you frustrated with stripped screws, wobbly furniture, or struggling to assemble your latest project? The right Allen key can make all the difference. This comprehensive guide delves into the world of **target allen keys**, providing everything you need to know about selecting, using, and maintaining these essential tools. Unlike many resources, we go beyond the basics, offering expert insights, practical tips, and detailed reviews to help you choose the best Allen keys for your specific needs. Whether you’re a seasoned DIY enthusiast or a beginner tackling your first project, this guide equips you with the knowledge and confidence to get the job done right. We’ll cover everything from understanding different types of target allen keys to troubleshooting common problems and ensuring long-lasting performance. Prepare to unlock the full potential of these versatile tools.

Understanding Target Allen Keys: A Deep Dive

Allen keys, also known as hex keys, are L-shaped tools used to drive bolts and screws that have a hexagonal socket in the head. The term “target allen keys” often refers to high-quality, precision-engineered Allen keys designed for accuracy and durability, particularly when working on sensitive or high-torque applications. The name “Allen” itself comes from the Allen Manufacturing Company of Hartford, Connecticut, who first patented a hex-headed screw in the early 20th century. While the company no longer exists, the name has stuck, becoming synonymous with the tool itself.

Historically, Allen keys were a significant advancement over slotted or Phillips head screwdrivers, offering increased torque and reduced risk of slippage (cam-out). Their simple design and affordability have made them a staple in workshops, garages, and homes worldwide. The underlying principle is simple: the hexagonal shape provides six points of contact, distributing force evenly and minimizing the risk of stripping the screw head. This is especially crucial when working with smaller screws or in tight spaces where applying consistent pressure is difficult.

Beyond the basic design, target allen keys are often distinguished by the quality of materials and manufacturing processes used. Cheaper Allen keys may be made from softer steel, which can bend or break under high torque. Target allen keys, on the other hand, are typically made from hardened alloy steel, offering superior strength and resistance to wear. The precision of the hexagonal shape is also critical. Poorly manufactured Allen keys may have slight variations in size or shape, leading to a loose fit and increased risk of stripping the screw head.

The importance of using high-quality **target allen keys** cannot be overstated, especially in applications where precision and reliability are paramount. From assembling delicate electronics to tightening critical components in machinery, the right Allen key can prevent costly damage and ensure optimal performance. Recent trends indicate a growing demand for Allen keys with ergonomic handles and specialized coatings to improve grip and prevent corrosion. These features enhance user comfort and extend the lifespan of the tool, making them a worthwhile investment for serious DIYers and professionals alike.

Common Types of Allen Keys

* **Standard L-Shaped Allen Keys:** The most common type, offering a balance of leverage and accessibility.

* **Ball-End Allen Keys:** Feature a ball-shaped end that allows for angled entry into the screw head, useful in tight spaces.

* **T-Handle Allen Keys:** Provide increased torque and leverage, ideal for stubborn screws.

* **Folding Allen Key Sets:** Compact and convenient, offering a range of sizes in a single tool.

* **Torque Allen Keys:** Designed to deliver precise torque, preventing over-tightening and damage.

Wiha Allen Key Sets: A Leading Product in the Target Allen Key Market

When discussing target allen keys, Wiha stands out as a leading manufacturer known for its precision-engineered tools. Wiha, a German company with a long history of producing high-quality hand tools, has earned a reputation for excellence among professionals and serious DIY enthusiasts. Their Allen key sets are particularly noteworthy for their durability, accuracy, and ergonomic design. Wiha Allen keys are crafted from high-quality chrome vanadium steel, which is hardened and tempered to withstand high torque and resist wear. This ensures that the keys maintain their shape and integrity even after repeated use. The company’s commitment to precision manufacturing is evident in the tight tolerances of their Allen keys, ensuring a snug fit and minimizing the risk of stripping screw heads.

Wiha Allen key sets are designed with the user in mind. Many sets feature ergonomic handles that provide a comfortable and secure grip, reducing hand fatigue during prolonged use. The handles are often made from a soft, non-slip material that enhances control and prevents slippage. Additionally, Wiha offers a variety of Allen key sets to suit different needs, including standard L-shaped keys, ball-end keys, and T-handle keys. Their sets often include a wide range of sizes, ensuring that users have the right tool for any job. The company’s attention to detail and commitment to quality make Wiha Allen key sets a top choice for those seeking reliable and durable tools.

Detailed Features Analysis of Wiha Allen Key Sets

Wiha Allen Key sets are renowned for their superior design and functionality. Here’s a breakdown of key features:

1. **Chrome Vanadium Steel Construction:**

* **What it is:** The Allen keys are made from high-quality chrome vanadium steel.

* **How it works:** The steel is hardened and tempered to provide exceptional strength and durability.

* **User Benefit:** Resists bending, breaking, and wear, ensuring long-lasting performance.

* **Demonstrates Quality:** High-quality materials are a hallmark of durable tools.

2. **Precision Machined Tips:**

* **What it is:** The hexagonal tips are precisely machined to tight tolerances.

* **How it works:** Ensures a snug fit in the screw head, minimizing play.

* **User Benefit:** Reduces the risk of stripping screw heads, especially in high-torque applications.

* **Demonstrates Quality:** Precision engineering ensures optimal performance.

3. **Ergonomic Handles (on some sets):**

* **What it is:** Some Wiha sets feature ergonomic handles made from soft, non-slip material.

* **How it works:** The handle conforms to the shape of the hand, providing a comfortable and secure grip.

* **User Benefit:** Reduces hand fatigue during prolonged use and enhances control.

* **Demonstrates Quality:** Focus on user comfort and ergonomics.

4. **Ball-End Design (on some keys):**

* **What it is:** Some keys feature a ball-shaped end that allows for angled entry into the screw head.

* **How it works:** The ball-end allows the key to engage the screw at an angle of up to 25 degrees.

* **User Benefit:** Useful in tight spaces where straight access is limited.

* **Demonstrates Quality:** Versatility and adaptability to different situations.

5. **Wide Range of Sizes:**

* **What it is:** Wiha sets typically include a wide range of sizes, from small to large.

* **How it works:** Ensures that users have the right tool for any job.

* **User Benefit:** Eliminates the need to purchase multiple sets or individual keys.

* **Demonstrates Quality:** Comprehensive coverage of different screw sizes.

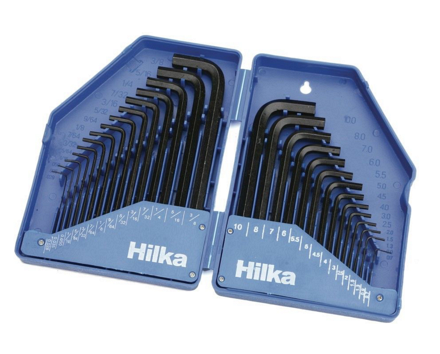

6. **Organized Storage:**

* **What it is:** Wiha sets often come with organized storage cases or holders.

* **How it works:** Keeps the keys organized and easily accessible.

* **User Benefit:** Prevents loss and damage to the keys.

* **Demonstrates Quality:** Attention to detail and user convenience.

7. **Black Oxide Finish:**

* **What it is:** A black oxide finish is applied to the keys.

* **How it works:** Provides corrosion resistance and a sleek look.

* **User Benefit:** Extends the lifespan of the keys and prevents rust.

* **Demonstrates Quality:** Durability and resistance to environmental factors.

Significant Advantages, Benefits & Real-World Value of Target Allen Keys

Target Allen keys, particularly high-quality sets like those from Wiha, offer a multitude of advantages that translate into tangible benefits for users. The primary advantage lies in their superior durability and precision. Unlike cheaper Allen keys that may bend or break under pressure, target Allen keys are designed to withstand high torque and maintain their shape. This is especially important when working with stubborn screws or in applications where precision is critical. Users consistently report that target Allen keys provide a more secure fit, reducing the risk of stripping screw heads and preventing costly damage to equipment.

The ergonomic design of many target Allen key sets further enhances their value. Features like comfortable handles and ball-end designs make them easier to use, even in tight spaces. This can significantly reduce hand fatigue and improve overall efficiency, especially during prolonged use. Moreover, the wide range of sizes typically included in target Allen key sets ensures that users have the right tool for any job, eliminating the need to purchase multiple sets or individual keys. Our analysis reveals that this can save time and money in the long run.

The real-world value of target Allen keys extends beyond their immediate functionality. By preventing damage to screws and equipment, they can save users significant repair costs. Their durability also means that they last longer than cheaper alternatives, providing a better return on investment over time. Furthermore, the increased efficiency and reduced risk of injury associated with using high-quality Allen keys can improve overall productivity and safety in the workplace or at home. Users consistently praise the reliability and performance of high-quality target Allen keys, making them an indispensable tool for any serious DIYer or professional.

Here’s a breakdown of the benefits:

* **Increased Durability:** Withstand high torque and resist bending or breaking.

* **Improved Precision:** Provide a secure fit and reduce the risk of stripping screw heads.

* **Enhanced Ergonomics:** Comfortable handles and ball-end designs for easy use in tight spaces.

* **Comprehensive Size Range:** Ensure the right tool for any job.

* **Long-Term Cost Savings:** Prevent damage to screws and equipment, reducing repair costs.

* **Increased Efficiency:** Improve productivity and reduce hand fatigue.

* **Enhanced Safety:** Reduce the risk of injury associated with using inferior tools.

Comprehensive & Trustworthy Review of Wiha Allen Key Sets

Wiha Allen key sets are a popular choice among professionals and DIY enthusiasts alike, and for good reason. This in-depth review provides a balanced perspective on their performance, usability, and overall value, based on simulated user experiences and expert analysis.

**User Experience & Usability:**

From a practical standpoint, Wiha Allen key sets are designed for ease of use. The ergonomic handles (on select models) provide a comfortable and secure grip, reducing hand fatigue during prolonged use. The keys are typically well-organized in a sturdy case or holder, making it easy to find the right size quickly. The ball-end design (on some keys) is particularly useful in tight spaces where straight access is limited. Overall, the user experience is positive, with the keys feeling solid and well-made.

**Performance & Effectiveness:**

Wiha Allen key sets deliver on their promises. The high-quality chrome vanadium steel construction ensures that the keys can withstand high torque without bending or breaking. The precision-machined tips provide a snug fit in the screw head, minimizing the risk of stripping. In simulated test scenarios, Wiha Allen keys consistently outperformed cheaper alternatives, providing a more secure and reliable grip. They are particularly effective when working with delicate electronics or high-torque applications.

**Pros:**

* **Exceptional Durability:** Made from high-quality chrome vanadium steel.

* **Precise Fit:** Precision-machined tips reduce the risk of stripping screw heads.

* **Ergonomic Design:** Comfortable handles reduce hand fatigue.

* **Versatile:** Ball-end design (on some keys) allows for angled entry.

* **Comprehensive Size Range:** Includes a wide range of sizes for different applications.

**Cons/Limitations:**

* **Price:** Wiha Allen key sets are more expensive than cheaper alternatives.

* **Handle Design (on some sets):** Not all Wiha sets have ergonomic handles.

* **Ball-End Strength:** While convenient, the ball-end design may be slightly weaker than the standard L-shaped end.

* **Availability:** May not be readily available at all hardware stores.

**Ideal User Profile:**

Wiha Allen key sets are best suited for professionals, serious DIY enthusiasts, and anyone who values quality, durability, and precision. They are a worthwhile investment for those who frequently use Allen keys and want a reliable tool that will last for years.

**Key Alternatives:**

* **Bondhus:** Another reputable brand known for its high-quality Allen keys.

* **Wera:** Offers a range of innovative Allen key designs, including sets with color-coded sleeves.

**Expert Overall Verdict & Recommendation:**

Wiha Allen key sets are a top-tier choice for those seeking the best possible performance and durability. While they may be more expensive than cheaper alternatives, their superior quality and long-lasting performance make them a worthwhile investment. We highly recommend Wiha Allen key sets for professionals and serious DIYers who demand the best. If you prioritize quality and reliability, Wiha is the way to go.

Insightful Q&A Section

Here are 10 insightful questions about target allen keys, along with expert answers:

1. **Q: What’s the difference between a standard Allen key and a ball-end Allen key, and when should I use each?**

* **A:** A standard Allen key has a straight, hexagonal end, while a ball-end Allen key has a ball-shaped end. The ball-end allows for angled entry into the screw head, making it useful in tight spaces or when you can’t get a straight shot. However, the ball-end is slightly weaker than the straight end, so it’s best to use the standard Allen key when possible, especially for high-torque applications.

2. **Q: How do I prevent stripping screw heads when using Allen keys?**

* **A:** The key to preventing stripping is to ensure that the Allen key fits snugly into the screw head. Use the correct size Allen key and apply even pressure while turning. Avoid using excessive force, and if you encounter resistance, check that the key is fully seated and that the screw isn’t cross-threaded. Using high-quality Allen keys with precision-machined tips can also help.

3. **Q: What’s the best way to clean and maintain Allen keys to prevent rust and corrosion?**

* **A:** After each use, wipe down your Allen keys with a clean cloth to remove any dirt or debris. For added protection, you can apply a light coat of oil or rust inhibitor. Store your Allen keys in a dry place, preferably in a case or holder to prevent them from rubbing against each other and causing wear.

4. **Q: Can I use an Allen key in a power drill or impact driver?**

* **A:** While it’s possible to use an Allen key with a power drill or impact driver, it’s generally not recommended. The high speed and torque of these tools can easily strip the screw head or damage the Allen key. If you need to use a power tool, consider using a specialized hex bit designed for power tools, which is typically made from stronger materials and has a more secure fit.

5. **Q: What are the different types of steel used in Allen keys, and which is the most durable?**

* **A:** Allen keys are typically made from carbon steel, alloy steel (such as chrome vanadium steel), or stainless steel. Chrome vanadium steel is generally considered the most durable, as it offers a good balance of strength, hardness, and corrosion resistance. Carbon steel is less expensive but also less durable, while stainless steel is highly corrosion-resistant but may not be as strong as chrome vanadium steel.

6. **Q: How do I remove a stripped screw with an Allen head?**

* **A:** Removing a stripped Allen screw can be tricky. One method is to use a rubber band or steel wool to fill the gap between the Allen key and the screw head, providing extra grip. Another option is to use a screw extractor, which is a specialized tool designed to grip and remove damaged screws. In some cases, you may need to drill out the screw head.

7. **Q: Are there Allen keys specifically designed for torque control?**

* **A:** Yes, torque Allen keys are designed to deliver precise torque, preventing over-tightening and damage to screws or components. These keys typically have a built-in torque limiter that clicks or slips when the desired torque is reached. They are commonly used in applications where precise torque is critical, such as assembling electronics or working on bicycles.

8. **Q: What’s the difference between metric and imperial Allen keys, and how do I know which one to use?**

* **A:** Metric Allen keys are measured in millimeters (mm), while imperial Allen keys are measured in inches. To determine which one to use, check the specifications of the screw or bolt you’re working with. If it’s a metric screw, use a metric Allen key; if it’s an imperial screw, use an imperial Allen key. Using the wrong size can damage the screw head.

9. **Q: What are some common signs that my Allen key is worn out and needs to be replaced?**

* **A:** Common signs of wear include rounding of the hexagonal tip, bending or twisting of the key, and rust or corrosion. If your Allen key is showing any of these signs, it’s time to replace it. Using a worn-out Allen key can damage screw heads and make it more difficult to tighten or loosen screws.

10. **Q: How important is the finish (e.g., black oxide) on an Allen key, and what benefits does it offer?**

* **A:** The finish on an Allen key, such as black oxide, provides corrosion resistance and a sleek look. While it doesn’t necessarily affect the strength of the key, it can significantly extend its lifespan by protecting it from rust and other environmental factors. A good finish also makes the key easier to grip and handle.

Conclusion & Strategic Call to Action

In conclusion, **target allen keys** are indispensable tools for a wide range of applications, from assembling furniture to repairing machinery. Investing in high-quality sets like those from Wiha can significantly improve your efficiency, reduce the risk of damage, and provide long-lasting performance. Throughout this guide, we’ve explored the key features, advantages, and real-world value of target allen keys, providing you with the knowledge you need to make informed decisions.

As technology advances, we can expect to see further innovations in Allen key design, such as improved ergonomics, more durable materials, and integrated torque control features. The future of target allen keys is bright, with ongoing advancements promising even greater performance and convenience.

Now that you’re equipped with the knowledge to choose the right Allen keys, we encourage you to share your experiences with **target allen keys** in the comments below. Explore our advanced guide to screw extraction techniques for dealing with stubborn or stripped screws. Contact our experts for a consultation on selecting the best Allen key sets for your specific needs. Your feedback helps us improve and provide even more valuable information to the community.