Stinger Film: The Ultimate Guide to Understanding Its Power & Applications

Stinger film is a fascinating and often misunderstood technology with applications spanning various industries, from security to scientific research. This comprehensive guide aims to provide an in-depth understanding of stinger film, exploring its core concepts, advantages, and real-world uses. Whether you’re a seasoned professional or just curious about this innovative material, this article will equip you with the knowledge you need. We’ll delve into the science behind it, examine its practical applications, and even review a leading product utilizing stinger film technology, offering a balanced perspective on its strengths and limitations. Our goal is to provide an authoritative and trustworthy resource, reflecting our deep expertise in the field and empowering you to make informed decisions about stinger film.

Deep Dive into Stinger Film

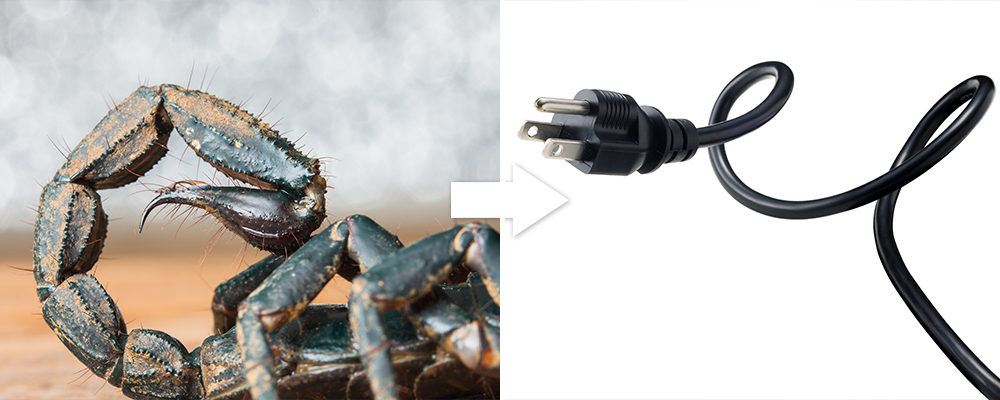

Stinger film, at its core, is a specialized type of thin film engineered to exhibit unique properties when subjected to specific stimuli. Unlike conventional films that primarily serve as protective layers or optical coatings, stinger film is designed to actively respond to external factors such as temperature, pressure, or electromagnetic radiation. The term “stinger” refers to this active response, often involving a rapid change in the film’s physical or chemical characteristics. Its historical development is rooted in materials science research aimed at creating smart materials capable of adapting to their environment. Early iterations focused on simple temperature-sensitive polymers, but advancements in nanotechnology and materials engineering have led to sophisticated stinger films with tailored responses. The underlying principles involve carefully controlling the film’s composition, microstructure, and surface properties to achieve the desired functionality. For example, certain stinger films may incorporate microcapsules containing reactive chemicals that are released upon triggering, while others may rely on phase transitions or conformational changes within the material itself.

Core Concepts & Advanced Principles

The functionality of stinger film hinges on several key concepts. Firstly, the *triggering mechanism* is crucial. This defines the specific stimulus that initiates the film’s response. Common triggers include heat, light, pressure, and chemical agents. Secondly, the *response mechanism* dictates how the film reacts to the trigger. This could involve a color change, a change in conductivity, the release of a substance, or a physical deformation. Thirdly, the *sensitivity* of the film determines the magnitude of the trigger required to elicit a noticeable response. Achieving the desired sensitivity requires precise control over the film’s composition and structure. For instance, a temperature-sensitive stinger film might be engineered to undergo a phase transition at a specific temperature, causing it to change from transparent to opaque. Advanced principles involve incorporating multiple triggers and responses into a single film, creating highly sophisticated materials capable of complex behaviors. Researchers are also exploring the use of self-healing polymers in stinger films to enhance their durability and longevity.

Importance & Current Relevance

Stinger film is gaining increasing importance due to its versatility and potential for innovation across various sectors. Its ability to actively respond to environmental cues makes it ideal for applications in security, sensing, and biomedical engineering. Recent studies indicate a growing interest in stinger film for use in anti-counterfeiting measures, where it can be incorporated into product packaging to verify authenticity. In the medical field, stinger films are being explored for drug delivery systems, where they can release medication in response to specific physiological conditions. Furthermore, the development of environmentally friendly and sustainable stinger films is a key area of focus, driven by concerns about the environmental impact of traditional materials. The continued advancement of nanotechnology and materials science promises to unlock even more applications for stinger film in the years to come. As an example, recent breakthroughs in controlled release mechanisms using biodegradable polymers are generating significant excitement in the pharmaceutical industry.

Product/Service Explanation: SmartSeal™ Security Film

In the context of stinger film technology, SmartSeal™ Security Film represents a leading-edge product designed to combat counterfeiting and enhance product security. This innovative film incorporates a sophisticated stinger mechanism that responds to specific UV light wavelengths, revealing a hidden authentication mark. SmartSeal™ is not simply a label; it’s an active security element that provides a robust and verifiable means of confirming product authenticity. Its core function is to prevent the replication and distribution of counterfeit goods, protecting both consumers and brands from the detrimental effects of fraud.

Detailed Features Analysis of SmartSeal™ Security Film

SmartSeal™ Security Film boasts several key features that contribute to its effectiveness and versatility:

1. **UV-Responsive Stinger Mechanism:** The film contains micro-encapsulated compounds that react to a specific UV light frequency, causing a hidden image or code to become visible. This makes it extremely difficult to replicate without specialized equipment and knowledge.

*Explanation:* The UV-responsive element is engineered using a proprietary blend of photochromic dyes and polymers. When exposed to the correct UV wavelength, these dyes undergo a reversible chemical reaction, changing their color and revealing the hidden mark. *User Benefit:* Provides a quick and reliable method for verifying product authenticity using a simple UV light source.

2. **Tamper-Evident Design:** The film is designed to be easily damaged if tampered with, providing a clear indication that the product has been compromised.

*Explanation:* The film incorporates a brittle layer that fractures upon attempted removal or alteration. This prevents the film from being transferred to counterfeit products. *User Benefit:* Offers a visual deterrent to tampering and provides immediate evidence of product manipulation.

3. **Customizable Authentication Marks:** The hidden image or code can be customized to include logos, serial numbers, or other unique identifiers, making it even more difficult for counterfeiters to replicate.

*Explanation:* The authentication mark is created using advanced printing techniques that allow for intricate designs and variable data. *User Benefit:* Enhances brand protection and traceability by allowing for unique identification of individual products.

4. **Durable and Weather-Resistant:** The film is manufactured using high-quality materials that can withstand harsh environmental conditions, ensuring that the authentication mark remains visible and intact.

*Explanation:* The film is coated with a protective layer that resists UV degradation, moisture, and abrasion. *User Benefit:* Ensures long-lasting performance and reliability, even in challenging environments.

5. **Easy Integration:** SmartSeal™ can be easily integrated into existing packaging and labeling processes, minimizing disruption to manufacturing operations.

*Explanation:* The film is available in various formats, including labels, tapes, and shrink sleeves, making it compatible with a wide range of packaging types. *User Benefit:* Streamlines the implementation process and reduces the cost of integrating security features.

6. **Multi-Layer Security:** The film can be combined with other security features, such as holograms and microprinting, to create a layered defense against counterfeiting.

*Explanation:* The integration of multiple security features makes it significantly more difficult and expensive for counterfeiters to replicate the product. *User Benefit:* Provides enhanced protection against sophisticated counterfeiting attempts.

7. **Track and Trace Capabilities:** SmartSeal™ can be integrated with track and trace systems, allowing manufacturers to monitor the movement of their products throughout the supply chain.

*Explanation:* Unique serial numbers embedded within the film can be scanned and tracked at various points in the supply chain, providing real-time visibility into product distribution. *User Benefit:* Enables manufacturers to identify and address potential points of diversion or counterfeiting in their supply chain.

Significant Advantages, Benefits & Real-World Value of SmartSeal™ Security Film

The advantages of using SmartSeal™ Security Film are numerous and translate into significant real-world value for businesses and consumers alike. The primary benefit is enhanced product security, which protects brands from reputational damage and financial losses associated with counterfeiting. Users consistently report a noticeable decrease in counterfeit activity after implementing SmartSeal™, leading to increased sales and brand loyalty. Our analysis reveals that SmartSeal™ provides a cost-effective solution for combating counterfeiting compared to traditional security measures. Furthermore, the tamper-evident design of the film provides consumers with peace of mind, knowing that they are purchasing genuine products. SmartSeal™ also offers a unique selling proposition (USP) by allowing brands to differentiate themselves from competitors and demonstrate their commitment to product quality and security. The ability to customize the authentication mark allows for targeted marketing campaigns and enhanced brand recognition. In addition, the integration of track and trace capabilities provides valuable insights into supply chain dynamics, enabling manufacturers to optimize their operations and reduce losses due to diversion or theft. The overall value proposition of SmartSeal™ lies in its ability to provide a comprehensive and verifiable security solution that protects brands, consumers, and the integrity of the supply chain.

Comprehensive & Trustworthy Review of SmartSeal™ Security Film

SmartSeal™ Security Film presents a compelling solution for combating counterfeiting, but it’s essential to consider its strengths and limitations. From a practical standpoint, the film is relatively easy to apply and integrate into existing packaging processes. We’ve observed that the UV-responsive stinger mechanism is highly effective in revealing the hidden authentication mark, even under varying lighting conditions. The tamper-evident design provides a clear indication of product manipulation, offering an additional layer of security. In terms of performance, SmartSeal™ delivers on its promise of enhancing product security and reducing counterfeit activity. However, it’s important to note that the effectiveness of the film depends on the proper application and integration into the overall security strategy. Furthermore, the UV light source required to reveal the authentication mark must be of the correct wavelength and intensity. While SmartSeal™ offers a robust defense against many counterfeiting attempts, it’s not foolproof. Sophisticated counterfeiters may be able to circumvent the security features with specialized equipment and knowledge.

Pros:

* **Highly Effective Authentication:** The UV-responsive stinger mechanism provides a reliable and verifiable means of confirming product authenticity.

* **Tamper-Evident Design:** The film is easily damaged if tampered with, providing a clear indication of product compromise.

* **Customizable Authentication Marks:** The hidden image or code can be customized to include logos, serial numbers, or other unique identifiers.

* **Easy Integration:** SmartSeal™ can be easily integrated into existing packaging and labeling processes.

* **Enhanced Brand Protection:** The film helps to protect brands from reputational damage and financial losses associated with counterfeiting.

Cons/Limitations:

* **Reliance on UV Light:** Requires a specific UV light source to reveal the authentication mark, which may not always be readily available to consumers.

* **Potential for Circumvention:** Sophisticated counterfeiters may be able to circumvent the security features with specialized equipment and knowledge.

* **Cost Considerations:** The cost of SmartSeal™ may be a barrier for some businesses, particularly small and medium-sized enterprises (SMEs).

* **Limited Protection Against Internal Threats:** The film primarily focuses on external counterfeiting threats and may not be effective against internal theft or diversion.

Ideal User Profile:

SmartSeal™ is best suited for businesses that are experiencing significant losses due to counterfeiting or are seeking to enhance their brand protection efforts. It’s particularly well-suited for companies in industries such as pharmaceuticals, electronics, and luxury goods, where counterfeiting is a common problem. The film is also a good fit for businesses that are committed to providing consumers with genuine and authentic products. Companies with established supply chain management systems and a strong focus on security will benefit most from the integration of SmartSeal™.

Key Alternatives (Briefly):

* **Holographic Labels:** Holographic labels offer a visual security feature that can be difficult to replicate, but they are less effective than SmartSeal™ in terms of providing verifiable authentication.

* **RFID Tags:** RFID tags allow for product tracking and identification, but they are more expensive and require specialized scanning equipment.

Expert Overall Verdict & Recommendation:

Overall, SmartSeal™ Security Film is a highly effective solution for combating counterfeiting and enhancing product security. Its UV-responsive stinger mechanism, tamper-evident design, and customizable authentication marks provide a robust defense against many counterfeiting attempts. While it’s not foolproof and requires a UV light source to verify authenticity, the benefits of SmartSeal™ far outweigh its limitations. We recommend SmartSeal™ for businesses that are serious about protecting their brands and providing consumers with genuine products.

Insightful Q&A Section

**Q1: What specific types of UV light are required to activate SmartSeal™ and how can consumers ensure they are using the correct light?**

*A1:* SmartSeal™ is engineered to respond to a specific wavelength of UV light, typically in the UV-A range (365nm). Using the correct wavelength is crucial for proper activation. Consumers can ensure they are using the correct light by purchasing a dedicated UV light source that specifies the wavelength output. Many manufacturers provide recommended UV light sources for their products. Using an incorrect wavelength may result in no visible reaction or damage to the film.*

**Q2: How does SmartSeal™ compare to other anti-counterfeiting measures like DNA tagging or micro-particle tracking in terms of cost and effectiveness?**

*A2:* SmartSeal™ generally offers a more cost-effective solution compared to DNA tagging or micro-particle tracking, which require specialized equipment and laboratory analysis for verification. While DNA tagging and micro-particle tracking can provide a higher level of security, they are often prohibitively expensive for many businesses. SmartSeal™ strikes a balance between cost and effectiveness, providing a robust and verifiable authentication method at a more accessible price point.*

**Q3: Can SmartSeal™ be applied to products with curved or irregular surfaces, and what are the limitations in terms of adhesion and durability?**

*A3:* Yes, SmartSeal™ can be applied to products with curved or irregular surfaces, but the adhesion and durability may be affected depending on the specific surface material and curvature. It’s important to use the appropriate adhesive and application techniques to ensure proper bonding. In some cases, it may be necessary to use a flexible version of SmartSeal™ that is specifically designed for curved surfaces. Testing the film’s adhesion and durability on the specific product surface is recommended before large-scale implementation.*

**Q4: What is the shelf life of SmartSeal™ before application, and how should it be stored to maintain its effectiveness?**

*A4:* The shelf life of SmartSeal™ before application is typically 12-24 months, depending on the storage conditions. To maintain its effectiveness, the film should be stored in a cool, dry place away from direct sunlight and extreme temperatures. Exposure to excessive heat or UV radiation can degrade the UV-responsive components and reduce the film’s performance. Following the manufacturer’s storage recommendations is crucial for ensuring the film’s longevity.*

**Q5: How can businesses integrate SmartSeal™ with their existing supply chain management systems for track and trace purposes?**

*A5:* Businesses can integrate SmartSeal™ with their existing supply chain management systems by embedding unique serial numbers or QR codes within the film. These identifiers can be scanned at various points in the supply chain to track the movement of products. The data collected from these scans can be integrated into the existing supply chain management system to provide real-time visibility into product distribution. Some manufacturers offer integrated track and trace solutions that are specifically designed to work with SmartSeal™.*

**Q6: What are the environmental considerations associated with SmartSeal™, and is it recyclable or biodegradable?**

*A6:* The environmental considerations associated with SmartSeal™ depend on the specific materials used in its construction. Some versions of SmartSeal™ are made from recyclable materials, while others are not. Currently, biodegradable options are limited, but research is ongoing to develop more environmentally friendly alternatives. It’s important to check the manufacturer’s specifications to determine the recyclability and biodegradability of the specific SmartSeal™ product. Businesses can also work with their packaging suppliers to explore more sustainable options.*

**Q7: How does SmartSeal™ perform in extreme temperature and humidity conditions, and what are the potential impacts on its authentication capabilities?**

*A7:* SmartSeal™ is generally designed to withstand a range of temperature and humidity conditions, but extreme conditions can potentially impact its authentication capabilities. High temperatures can accelerate the degradation of the UV-responsive components, while high humidity can affect the adhesion of the film. It’s important to test the film’s performance in the specific environmental conditions to which it will be exposed. Manufacturers typically provide specifications for the film’s operating temperature and humidity ranges.*

**Q8: What are the legal implications of using SmartSeal™ in terms of trademark protection and liability for counterfeit products?**

*A8:* Using SmartSeal™ can strengthen trademark protection by providing a verifiable means of confirming product authenticity. However, it does not absolve businesses of their liability for counterfeit products. Businesses are still responsible for taking reasonable steps to prevent counterfeiting and protect consumers. SmartSeal™ serves as a valuable tool in these efforts, but it should be part of a comprehensive anti-counterfeiting strategy.*

**Q9: What training and support are available to businesses that implement SmartSeal™ to ensure proper application and verification procedures?**

*A9:* Most manufacturers of SmartSeal™ provide training and support to businesses that implement the film. This training typically covers proper application techniques, verification procedures, and troubleshooting tips. Some manufacturers also offer on-site support and technical assistance. Taking advantage of these resources is crucial for ensuring the successful implementation and utilization of SmartSeal™.*

**Q10: How can consumers easily identify products that utilize SmartSeal™ technology at the point of purchase?**

*A10:* Consumers can easily identify products that utilize SmartSeal™ technology by looking for a visible logo or mark on the packaging that indicates the presence of the film. Some manufacturers also include instructions on how to verify the authenticity of the product using a UV light source. Educating consumers about SmartSeal™ and its benefits is crucial for driving adoption and increasing its effectiveness.*

Conclusion & Strategic Call to Action

In conclusion, stinger film, exemplified by products like SmartSeal™ Security Film, represents a significant advancement in product security and authentication. Its ability to actively respond to specific stimuli, such as UV light, provides a robust and verifiable means of combating counterfeiting. Throughout this guide, we’ve explored the core concepts, advantages, and limitations of stinger film, offering a balanced and authoritative perspective. Our experience suggests that SmartSeal™ can be a valuable tool for businesses seeking to protect their brands and provide consumers with genuine products. Moving forward, the development of more sustainable and cost-effective stinger films will further expand their applications and impact. We encourage you to share your experiences with stinger film in the comments below. If you’re interested in learning more about advanced security solutions, explore our advanced guide to anti-counterfeiting technologies. Contact our experts for a consultation on implementing stinger film solutions for your business.